Friday Update: Seven Two Twenty...

A week of contrasts, from large to small scale, scratch building the start of a build to weathering stages at the end of the build with a few phone calls and some CAD time thrown in too...

You'll of course be pleased to hear that the weather had a turn for the good this week though, with a few days of clear blue skies, still cold in the workshop but a lot nicer when glancing out the window than the gloom of January.

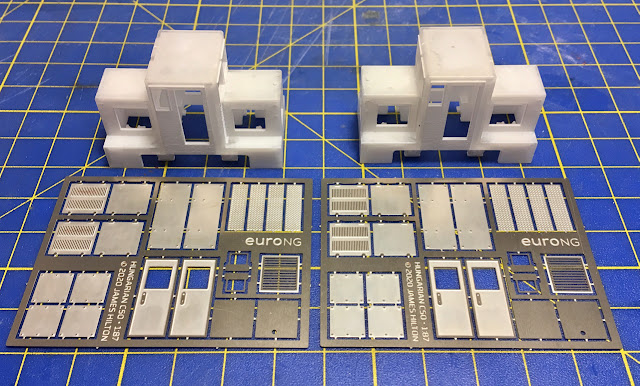

I received a box of parts from Steve earlier in the week with 3D printed Barclay cabs for me to check and clean up, as well as some etches for various locos, including a re-scale of the EuroNG C50 (released as an 009 model for the Bachmann Rusty chassis at ExpoNG in October) to H0e. This involved a re-draw of the artwork to ensure it worked in the smaller scale, thickening of some walls in the 3D artwork and removing the mounting points inside the design to leave a maximum of space to allow my customer to fit their own chassis design. It looks superb, and is positively tiny compared to the 009 version, it always surprises me the visual size difference between scales that often people say are 'interchangeable'!

The 7/8ths scale Ruston has begun to come to life under the first two stages of a four stage weathering. The model was first assembled (as it had been in parts for painting) before applying a 'thick' wash in panels at a time before wiping clean, which leaves a slight dirt across the whole panel, and especially around the bolt head detail. I left this for a day to harden before dry brushing gun metal on the metal edges, as well as quite heavily under the feet and around the controls to represent worn paint. The metallic particles left on the surfaces catch the light and bring the model to life. Next will be some detailed micro painting around panel lines, adding some scrapes etc before a little dirt with the airbrush to finish it off...

Planet Industrials has been on my mind a lot this week with three or four projects coming along at different stages. Above is the 'Version 2' of the Hibberd, this includes front foot steps and handrail, as well as a modified cab. The parts all fit but I'm going to look at a mild re-design to improve the look of the front end. We're not sure how we'll market these different variants - the two chassis types need different etches, and at present the new cab design is an extra etch 'in the box' with the chassis parts and cab on... this could be offered as an extra 'component' you can buy to modify the original version of the kit.

A customer has commissioned me to draw up the NCB style cab for the Hattons Barclay - the product of which is shown above. This has been modified from the Devonport artwork and is being test printed in both Shapeways and on our own 3D printer to check for any problems. We will be releasing this version of the cab towards the summer.

The Devonport example has now been fitted and painted to it's donor model - which has been lined with transfers I designed to fit (although the tank ones were a touch too long so I had to cut them diagonally and overlap them a touch which is just noticeable). I also replaced the saddle tank handrails with Eileen's short handrail knobs and 0.4mm wire to improve the 'bendy' look of the originals supplied with the model. This has received a coat of dull-cote but is awaiting weathering. All being well the kit will be out this month and will include the cab and etch parts.

Finally, I applied some of the forthcoming Planet Industrials transfers to the NCB wagon earlier in the week and have begun weathering this - so far only a wash but more to come, posed here with the DJ Models Austerity. I have a few things due in the post today from Hattons including some road vehicles to test out the NCB transfers on - so expect more on that next week and hoping to release them in the next fortnight once the header cards arrived.

Finally I've been working on this 1/12 scale 'Whimshire' esque model, having now added detail to the smokebox and tanks, as well as adding brass castings from the Talisman 7/8ths range including water filler kits (actually from the Hunslet Waril, but look great here) clack valves and smokebox door which is mounted on magnets to allow it to be removed (if necessary) to access the batteries. The dome and chimney are on spigots to allow them to be easily removed during the rest of the finishing. Next up though is the cab, and I may end up chickening out of scratch building this and look to the laser for some consistency in cutting four spectacle holes!

Next week will see some more Planet Industrials news as the first parts of the new Planet chassis I've designed come together for testing. I'm also hoping to begin work in anger on a modified Grafar N gauge 08 chassis to lengthen the wheelbase, a project I've been mulling over for a few months since I was commissioned to do a Worsley Works Lyd2. Enjoy the weekend, more soon...

Comments

Post a Comment

Thank you for leaving a comment on my blog - I appreciate you taking the time to share your views. If you struggle to log in, please turn off the ‘block cross-site tracking’ setting in your browser.

James.